Contact Us

Add 1:2512,Block A, Wanda Center, Xinghualing District, Taiyuan City, Shanxi Province. (Company office address)

Add 2:2006, Block C, Tianshan Galaxy Plaza, No. 358 Yuhua East Road, Shijiazhuang(Business license address)

E-mial:sales@xo-pump.com

WhatsApp: +8615680632715

E-mial:info@xo-pump.com

WhatsApp: +8615364966178

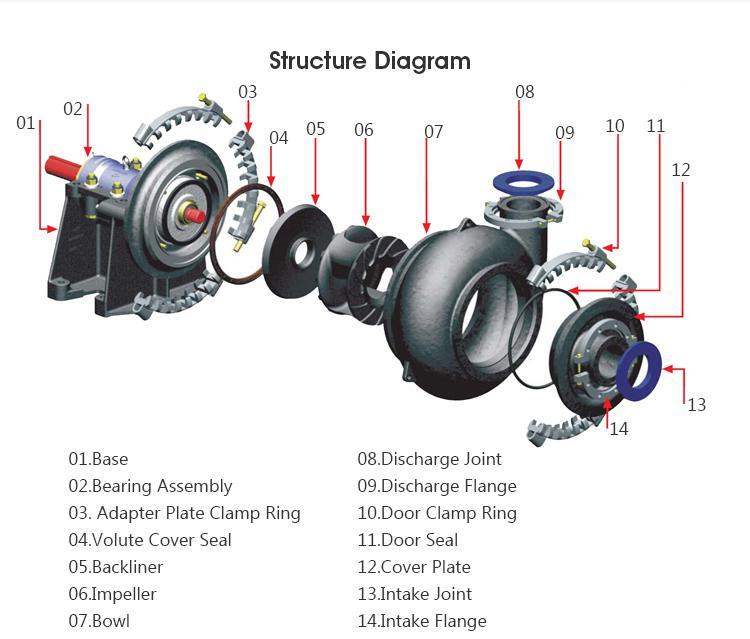

ZG(H) Series Sand, Gravel and Slurry Pump

- Commodity name: ZG(H) Series Sand, Gravel and Slurry Pump

- Description

-

The ZG(H) series gravel pump is designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. The Horizontal Centrifugal Gravel Pump is suitable for delivering slurries in mining, explosive sludge in metal melting, dredging and so on. Single casing with exceeded passage and lowered NPSHr makes gravel slurry pumps as a best selection for dredging, delivering sludge I mining plant.

Gravel Pump Range:

Parameter

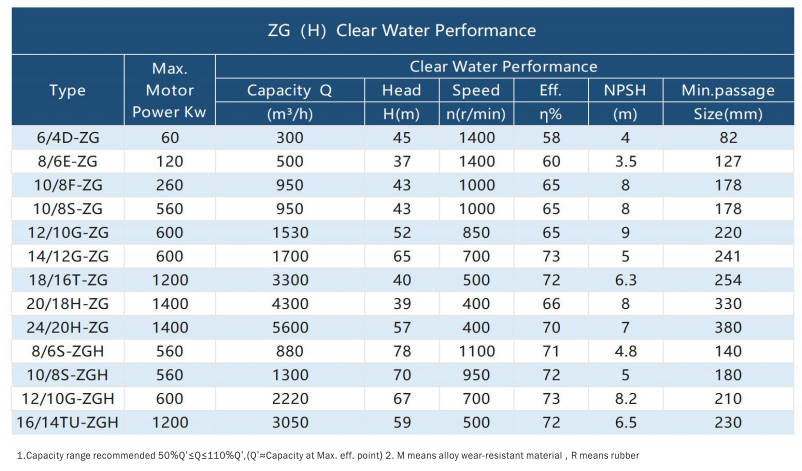

Caliber 40-200mm Maximum flow quantity 5600m³/h Maximum head 78m Speed 200-3800r/min Power 15-1200kw For details, please refer to the bottom clear water performance table.

Gravel Pump Typical Application:

(1) Coarse Sand

(2) Dredging

(3) Fine Tailings

(4) Coal

(5) Sugar

(6) Paper & Pulp

(7) Mineral Sands

Gravel Pump Features

1. The ZG(H) Series Gravel Pump is also called hopper dredging pump, it is a single suction mud pump that allows mud to be drawn only from one suction side. The single-stage horizontal cantilever pump adopts a single impeller structure and is widely used in industries such as dredging, mining and mineral processing.

2. A typical feature of such a hopper dredging pump is its integral housing. Other desirable features include high channel and wear resistant wet end sections made of high chrome.

3. Shaft seal selection: packing gland seal,centrifugal seal, mechanical seal.

4. The discharge outlets have 8 positions spaced at 45 degrees and can be selected to meet installation and application requirements.

Gravel Pump Advantages

1. Optimized slurry pump system layout simplifies maintenance operation, ensures long service life, and suit the pump for heavy duty tasks of pumping slurries with large solids.

2. One-piece case and wear-resistant hydraulic parts are easy to replace and repair.

3. Wide flow passage allows a large volume of slurry to pass. The sand and gravel slurry pumps are specially designed to handle high-abrasion applications that ordinary pumps can’t even attempt.

4. The gravel slurry pump head is fixed to the mounting base by a few bolts. Users can adjust the clearance between the impeller and suction liner from underneath a bearing pedestal.

5. Shaft seal options: packing gland seal, centrifugal seal, and mechanical seal. Users can easily replace one type of seal with another in order suit the specific pumping application.

Hydraulic Modeling

The wet end parts are cast from hard metal or polyurethane. Even when the dredging pumps are severely worn, they maintain good hydraulic performance. This helps the sand pump to achieve optimum pumping efficiency levels. The 3-bladed impeller increases the centrifugal gravel pump's ability to pass through the slurry.

Shaft Seals Packing Seal

As one of the most commonly used seals for rotating shafts, the gland seals can be placed in a low or full flush arrangement that uses flushing water to prevent media from escaping from the centrifugal gravel pump casing. This seal is suitable for almost all pumping applications. In the case of corrosive solids or high temperatures, polytetrafluoroethylene or aramid fibers are used as the sealing material. In order to further improve the wear resistance of the shaft, a ceramic coated bushing will be used.

Centrifugal Seal-Expeller

The combination of impeller and ejector creates a seal that prevents leakage. This seal, together with the seal or lilp seal used as a closure seal, can handle the sealing requirements of applications where full flush seals are not possible due to lack of water on site, or allow seal water to enter the hopper dredging pump chamber to dilute the slurry.

Installation Types of hopper dredging pump

DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the sand and gravel pump is the same as that of the motor.

CV Type: The pump is driven by a belt connected to the crankshaft of the engine. This way of connection allows for saving space, easy installation, and fast adjustment of pumping speed. The motor is fixed to the motor support frame which is located on the bearing pedestal above the pump.

ZV Type: Another type of belt drive that allows easy adjustment of pumping speed. The motor is directly fixed to the bearing pedestal. This way of installation is suitable for motors with larger horsepower than is possible with CV type of installation. Due to the installation of motor onto the bearing pedestal, this method helps save installation space.

CR Type: This type of belt drive makes it easier to adjust pumping speed. The installation allows both the motor and heavy duty dredge pump to be fixed to the ground. The motor is installed to the side of the sand and gravel pump. This installation method is suitable for large-power motors.

MG(H) clear water performance table

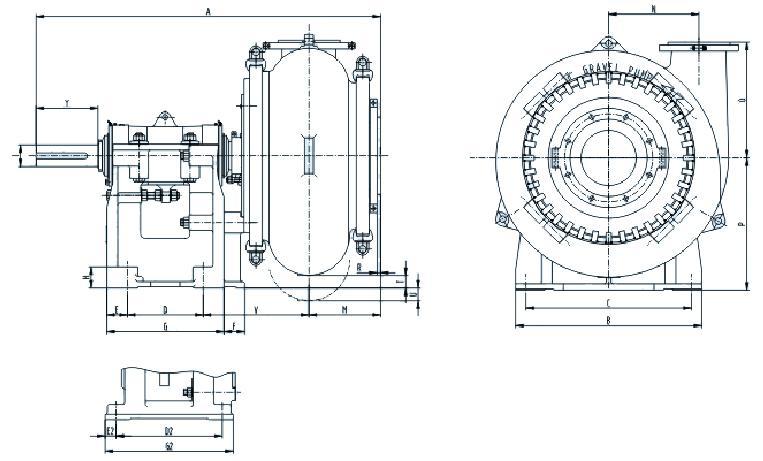

Outline drawing

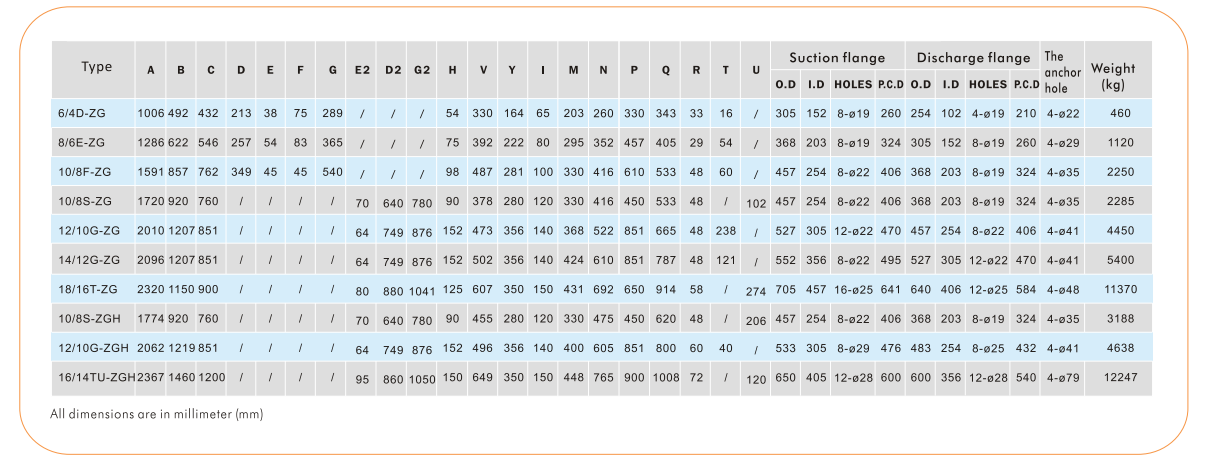

Outline Dimensions

All dimensions are in millimeters (mm)

Key words:

Product Packaging

Company Information

Shijiazhuang Zhengrong Pump Co., ltd., affiliated with Shijiazhuang Industrial Pump Co., ltd.Group, is a large-scale slurry pump manufacturing enterprise. ZR provides slurry pump and special alloy parts that feature a high performance and a wearing and corrosion resistance. First established in 1998, we now own three production bases with a dredge pump, desulphurization pump and slurry pump production base located in Shijiazhuang Development Zone, covering 46000 square meters.

ZR can complete the research and development of new products, due to our self-owned pump test station, which carries out tests with extreme accuracy to ensure all pumps meet international standards, and allow us to offer only the best products and materials to meet different operating conditions. We have a large mold database that includes a full range of advanced aluminum molds used to produce various industrial pump castings. Our company has an extensive inventory of standard pieces, allowing us to keep a delivery period to within 10 days of the order being placed. If standard products don’t meet your needs, supply us with special design drawings, and we will carry out custom OEM orders for even the most advanced EPC casing line. We work with numerous well-known domestic names, including the Waterway Bureau, mining companies, desulphurization companies and more, as well as partnerships with international corporation customers.

Our product line includes pumps and accessories, and OEM services, and has been sold around the world to customers from North and South America, Africa, Russia, Europe and Southeast Asia. Come check us out today, and let ZR show you what we have to offer for all of your slurry pump needs.

Our Services

1. Processing with supplied drawing

2. Processing with supplied samples

3. Produce all kinds of anti abrasive spare parts except for pump

Shipping And Payment

FAQ

How can I make order online?

Do you have MOQ limit?

Which payments are acceptable?

Which shipping terms are available?

How about the delivery time?

Can I purchase parts separately?

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products