Contact Us

Add 1:2512,Block A, Wanda Center, Xinghualing District, Taiyuan City, Shanxi Province. (Company office address)

Add 2:2006, Block C, Tianshan Galaxy Plaza, No. 358 Yuhua East Road, Shijiazhuang(Business license address)

E-mial:sales@xo-pump.com

WhatsApp: +8615680632715

E-mial:info@xo-pump.com

WhatsApp: +8615364966178

ZJ Series Sand and Slurry Pump

- Commodity name: ZJ Series Sand and Slurry Pump

- Description

-

ZJ series sand and slurry pump is a new type of anti-abrasion pump, belonging to axial, self-suction, single-stage, single suction, centrifugal slurry pumps. This series of pumps in the hydraulic design, structural design and the use of wear-resistant materials, combines the advantages of similar products at home and abroad as well as self-innovation, featured by high efficiency and energy-saving, small vibration, low noise, reliable operation, long service life and convenient maintenance. The overall performance ranks in the domestic leading level and most of the efficiency indicators in the international advanced level.

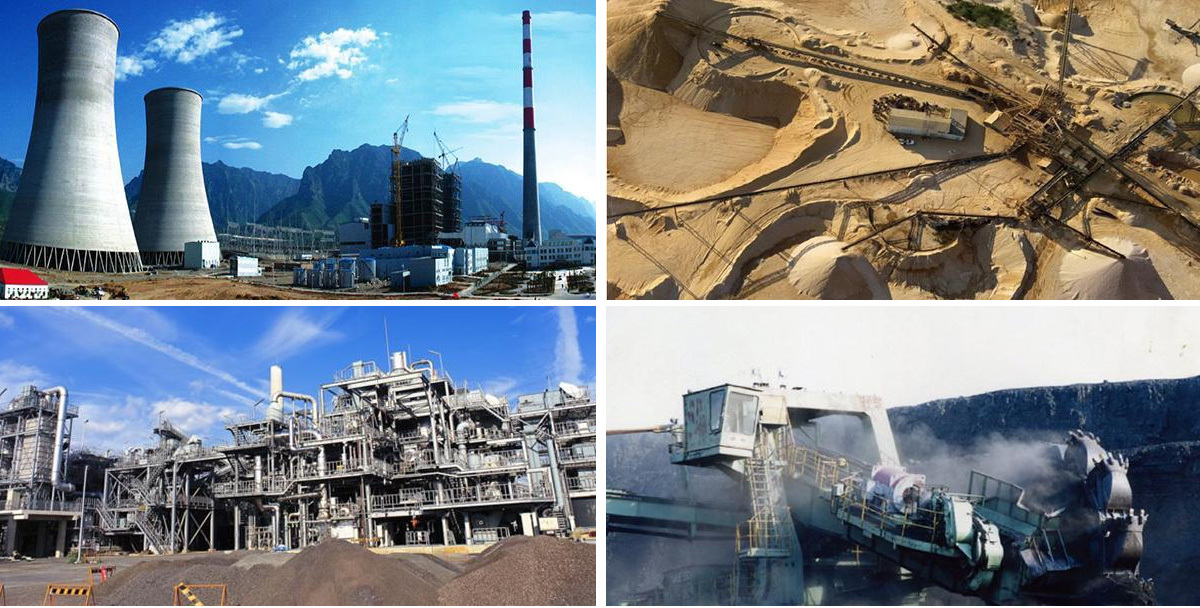

The pump can be widely used for transporting slurry with solid particles in the electric power, metallurgy, coal, building materials and other industries, such as hydraulic ash removal in power plant, slurry transportation in metallurgical concentrator, coal slurry in coal preparation plant and transportation of heavy medium, etc.

The maximum slurry weight concentration(Cw) of ZJ series sand and slurry pump: ash (slag) slurry and coal slurry is 45%; pulp and heavy medium is 60%.

Application

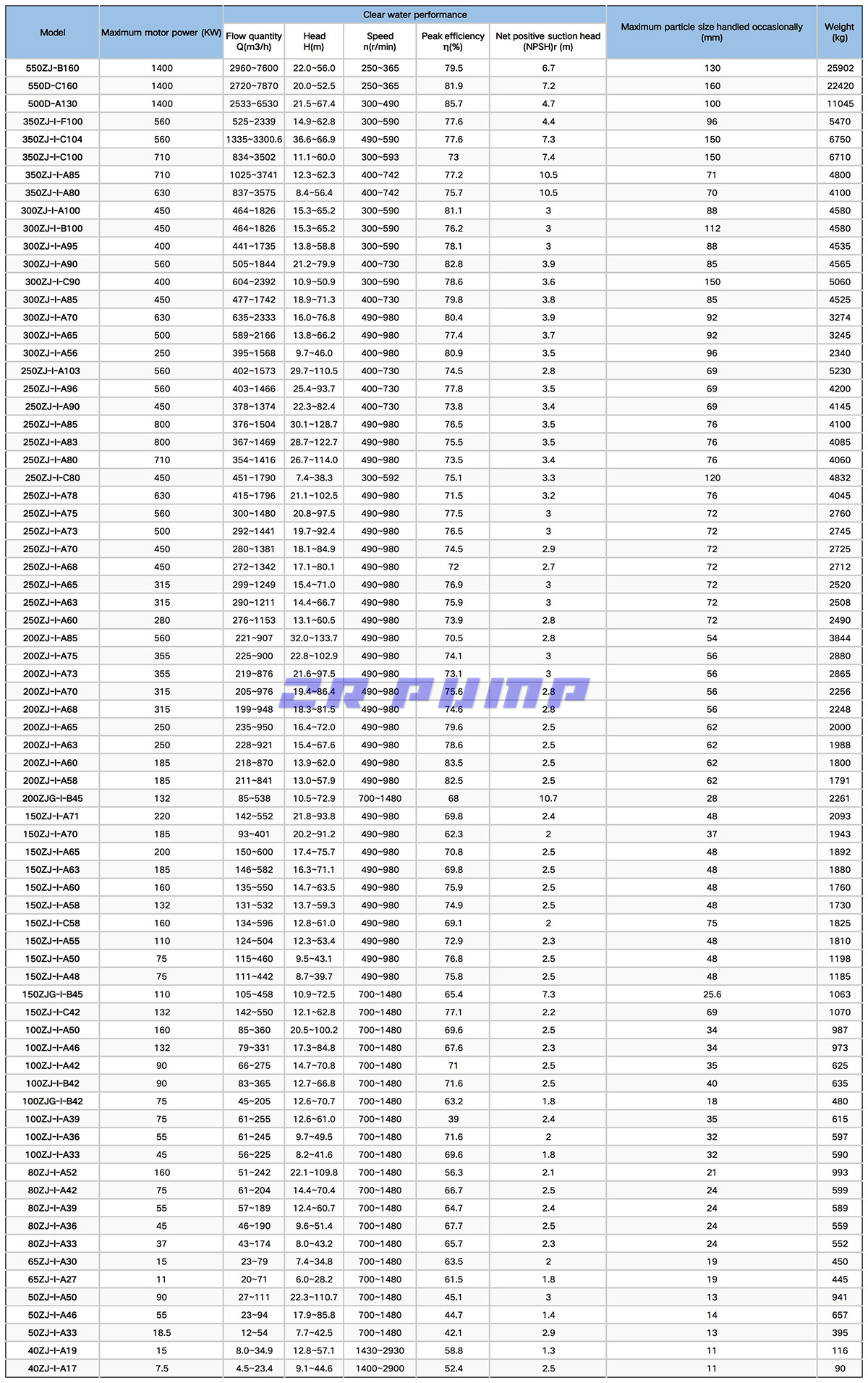

Parameter

Caliber 50-300mm Maximum flow quantity 2333m³/h Maximum head 133.7m Speed 300-1480r/min Power 11-800kw For details, please refer to the bottom clear water performance table.

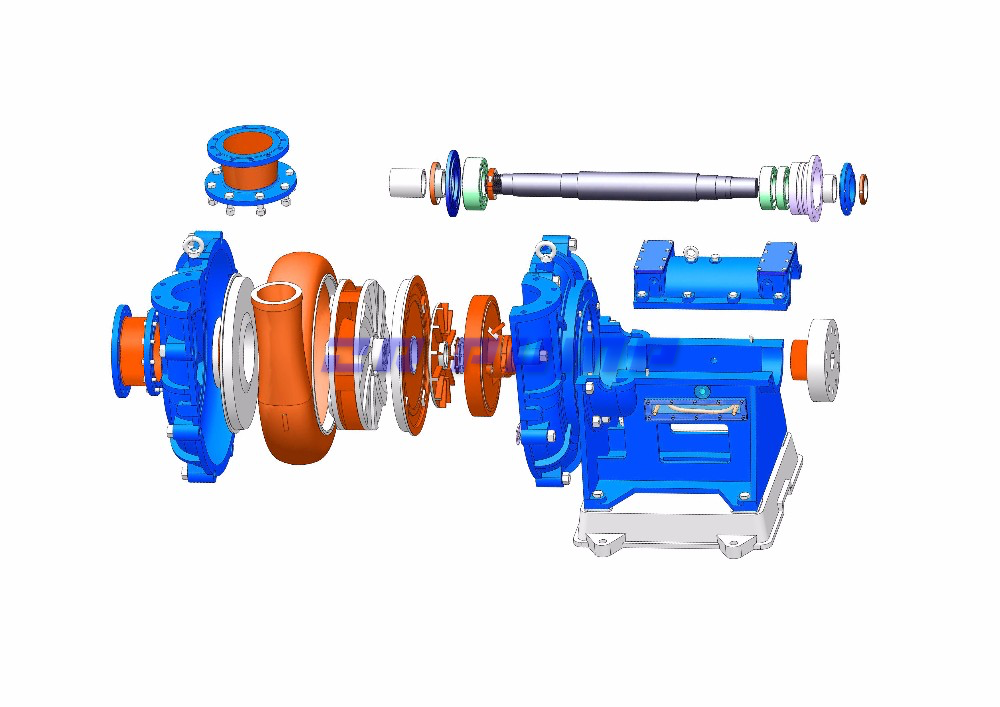

Structure drawing of ZJ series slurry pumps

Structural features

1. ZJ series sand and slurry pump: horizontal type

1) Pump head

The pump head of ZJ series pump comprises a pump casing, impeller and shaft sealing device. The pump head and the bracket are connected by bolt fastening. The outlet position of the pump can be rotated to eight different angles at the interval of 45 degrees for installation and use as required.

The pump casing adopts double-shell structure. The outer layer is a metal pump case (including the front and rear pump shells) usually made of HT200 or QT500-7; the inner layer can be manufactured by high chromium alloy cast iron (including the volute, front and rear guard plates), or rubber (including the front and rear volutes).

The impeller consists of front and rear cover plates, blades and back blades. The blades, usually are 3-6 twisted blades. While the number of back blades are usually 8, distributed on the outside of the front and rear cover plates. The impeller(made of high chromium alloy cast iron) and shaft adopt screwed connection.

The shaft sealing device has three forms: auxiliary impeller and packing combination seal, packing seal, mechanical seal.

The auxiliary impeller and packing combination seal form is composed of stuffing box, auxiliary impeller, seal cage, packing, packing gland and shaft sleeve.

The packing seal form consists of stuffing box, spacer sleeve, seal cage, packing, packing gland and shaft sleeve.

The mechanical seal form comprises stuffing box, spacer sleeve, mechanical seal, gland and shaft sleeve.

2) Bracket part

The bracket part has two structures: horizontal split type and cylinder type.

The horizontal split bracket has two types: oil lubrication and grease lubrication. The oil lubrication bracket is mainly composed of bracket body, bracket gland, shaft, bearing box, bearing, bearing gland, nut, grease seal and other parts. 150ZJ and above pumps are also equipped with water cooling unit.

Compared with oil lubrication bracket, the grease lubrication bracket adds the embedded bearing cover and oil cup, and removes water cooling device.

The cylinder bracket adopt grease lubrication, mainly composed of bracket body, bearing body, shaft, bearing, bearing gland, oil seal, oil cup and other parts, which is only suitable for 200ZJ and below pumps with low power.

2. ZJL series sand and slurry pump: vertical type

ZJL series sand and slurry pump is primarily composed of impeller, volute, rear guard plate, shaft sleeve, bracket, support plate, shaft, bearing, bearing body and other parts.

The impeller, volute and guard plate are all made of high chromium alloy cast iron; the impeller and shaft adopt screwed connection, while the volute, bracket and bearing body use bolt fastening.

The pump shaft and motor can use direct drive coupling or belt drive. Use grease lubrication for bearings. This series of pumps has no shaft seal.

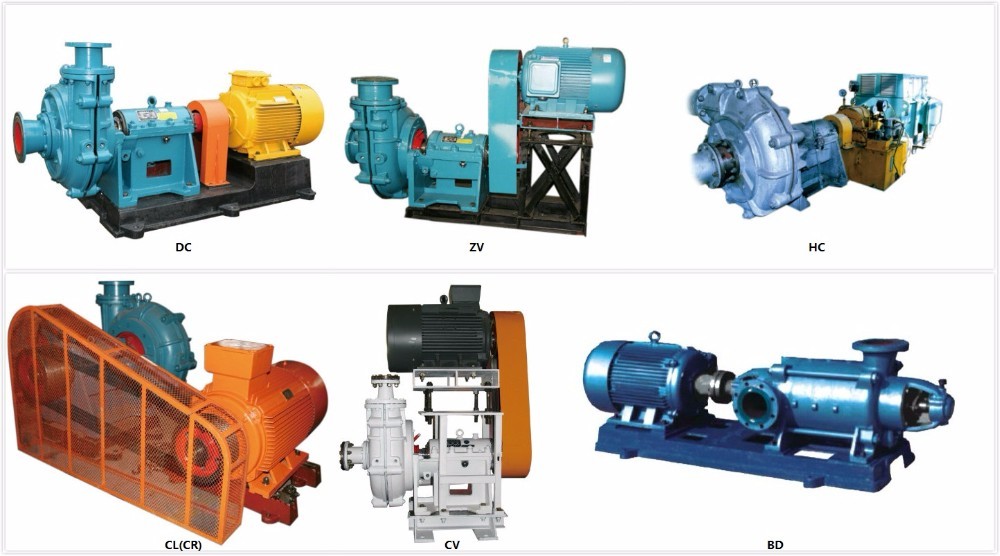

Driving patterns

Clear water performance table

Key words:

Product Packaging

Company Information

Shijiazhuang Zhengrong Pump Co., ltd., affiliated with Shijiazhuang Industrial Pump Co., ltd.Group, is a large-scale slurry pump manufacturing enterprise. ZR provides slurry pump and special alloy parts that feature a high performance and a wearing and corrosion resistance. First established in 1998, we now own three production bases with a dredge pump, desulphurization pump and slurry pump production base located in Shijiazhuang Development Zone, covering 46000 square meters.

ZR can complete the research and development of new products, due to our self-owned pump test station, which carries out tests with extreme accuracy to ensure all pumps meet international standards, and allow us to offer only the best products and materials to meet different operating conditions. We have a large mold database that includes a full range of advanced aluminum molds used to produce various industrial pump castings. Our company has an extensive inventory of standard pieces, allowing us to keep a delivery period to within 10 days of the order being placed. If standard products don’t meet your needs, supply us with special design drawings, and we will carry out custom OEM orders for even the most advanced EPC casing line. We work with numerous well-known domestic names, including the Waterway Bureau, mining companies, desulphurization companies and more, as well as partnerships with international corporation customers.

Our product line includes pumps and accessories, and OEM services, and has been sold around the world to customers from North and South America, Africa, Russia, Europe and Southeast Asia. Come check us out today, and let ZR show you what we have to offer for all of your slurry pump needs.

Our Services

1. Processing with supplied drawing

2. Processing with supplied samples

3. Produce all kinds of anti abrasive spare parts except for pump

Shipping And Payment

FAQ

How can I make order online?

Do you have MOQ limit?

Which payments are acceptable?

Which shipping terms are available?

How about the delivery time?

Can I purchase parts separately?

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products