Contact Us

Add 1:2512,Block A, Wanda Center, Xinghualing District, Taiyuan City, Shanxi Province. (Company office address)

Add 2:2006, Block C, Tianshan Galaxy Plaza, No. 358 Yuhua East Road, Shijiazhuang(Business license address)

E-mial:sales@xo-pump.com

WhatsApp: +8615680632715

E-mial:info@xo-pump.com

WhatsApp: +8615364966178

ZJQ Submersible slurry pump

- Commodity name: ZJQ Submersible slurry pump

- Description

-

OVERVIEW

slurry pump is developed and improved from ZJL (vertical slurry pump) and overcome its deficiency. What's more, the pumps are comprehensively optimized and innovatively designed in the hydraulic model, sealing technology, mechanical structure, and protection control. This series has simple structure, easy installation, safe and reliable use, and long life. The pump does not need to construct a complex ground room and fixtures when it is submerged. That makes the site cleaner without noise and vibratio.

MAIN USAGE

This series is suitable for conveying slurry with abrasive particles such as sand, cinder, tailings, etc. It is mainly used in metallurgy, mining, power, chemical industry, environmental protection, dredging, municipal engineering and other industries. It is easy to install and move. It also has high slag extraction efficiency and can safely run under bad working conditions. It is an ideal product to replace traditional vertical sump pump and submersible sewage pump.

WORKING CONDITION

1.Power supply: 380V, three-phase, 50HZ (customized voltage and frequency according to requirements).

2.Medium temperature is generally not more than 60C°, PH value 4-10, medium gravity W 1300kg/ m3.

3.Suitable for medium with strong abrasive solid particles and mildly corrosive sewage slurry.

4.The diameter of solids in the medium shall not be greater than 80% of the minimum port size of the pump.

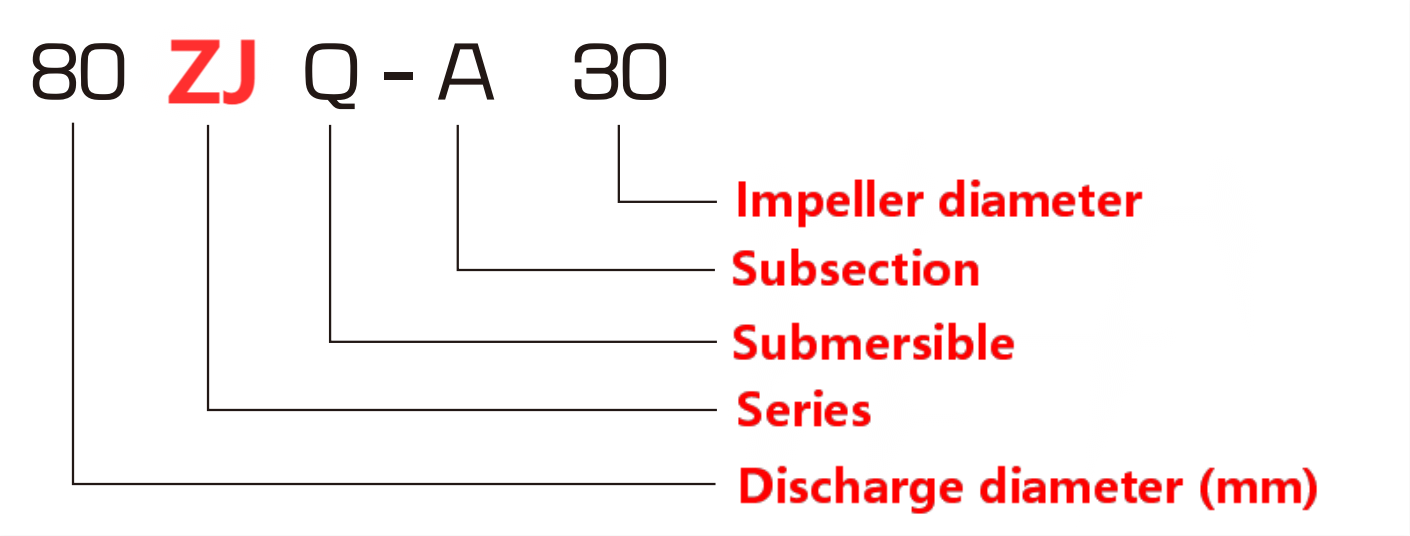

MODEL IMPLICATION

STRUCTURE DRAWING

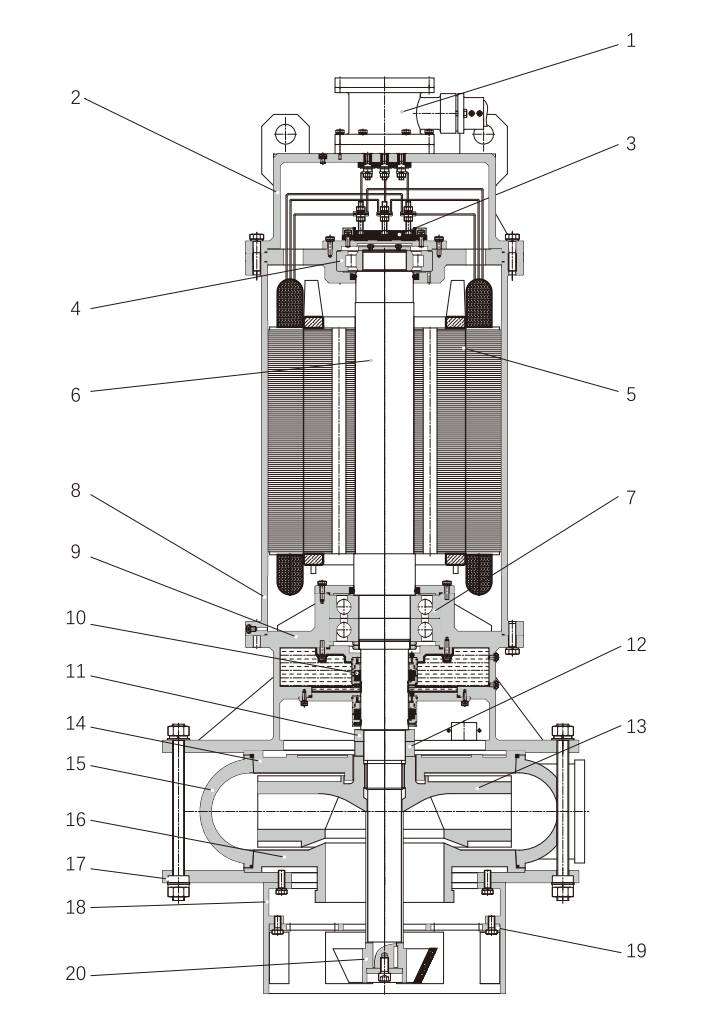

STRUCTURE SPECIFICATION

1.Casing and impeller

Based on the test, the casing and impeller are carefully selected and matched. The casing and impeller are made of high-chromium material. It has good non-clogging performance, high efficiency, flat power curve, unlikely to overload, accurate impeller balance, small vibration and stable operation.

2.Agitator

The stirring wheel is at the bottom of the pump. It can stir the deposited sediment in the bottom of the water into a turbulent flow and pump it. It integrates diving, stirring, sand blowing, and sand pumping. It has high efficiency and more thorough dredging.

3.Motor

The submersible motor is specially designed with IP68 protection and F-class insulation allows rising temperature. Under normal conditions of temperature rise, the motor has long insulation life, and good diving cooling effect. If the actual rising temperature is low, the motor insulation life would be longer.

4. Motor cooling

The motor dissipates heat through the casing. As long as the medium submerged half of the motor stator casing, it can operate reliably and safely. The more the motor is submerged, the better for motor's cooling

5.Shaft seal

The motor shaft seal adopts two independent mechanical seals in series to form two reliable sealing lines. The first is in the medium, and the sealing surface is pressed tighter as the medium pressure increases, preventing water from entering the oil chamber. And the second is in the oil chamber, preventing oil from entering the motor. Even if the first failed, the second one can still prevent oil and water from entering the motor. The bellows-type mechanical seal and the innovative structural cavity improve the reliability of the shaft seal. Under normal application, the trouble-free operating time exceeds 8000 hours.

6. Oil room

The oil chamber is the first barrier that prevents the medium from entering the motor from the shaft and prevents the medium from penetrating into the electrode. If the first mechanical seal leaks, the buffer medium in oil chamber cannot enter the motor directly. At the same time, lubricating and cooling the friction surfaces of two independent machine seals to make the machine seal work more reliably, besides it can also take away part of heat from the bearing and the motor.

7.Bearing

The double-row angular contact bearing at the bottom has a strong bearing capacity, which is combined with the upper deep groove bearing to form a reliable support for the motor pump shaft. It can form large bearing margin for the radial, axial and other forces generated during the operation of the sewage pump, which can ensure the stable operation and long service life.

8.Cable and seal

1) The cable is a heavy-duty rubber-sheathed flexible cable that is resistant to sewage. The cross-section of the cable core is designed for long-term reliable operation at 40 ° C ambient temperature and full load power of the motor. If the sewage pump works, the motor will operate under non-full load power or under 40C°, the service life will be longer.

2) The cable rubber sleeve and the motor gland are sealed and compressed to prevent the medium from infiltrating into the motor cavity between the cable and the motor cover.

3) There is rubber vulcanization between the cable sleeve and the core. Once the rubber jacket scratched, it can still prevent the medium from entering the motor from the cable sleeve.

9. Motor housing

The housing, the upper-end cover and the gland etc. constitute the motor cover, and the parts are connected and matched with reliable static seal. The pressure test will be applied to make sure there is no leakage.

10.Safety protection inside the pump (acting through the dedicated electric control cabinet)

1). Oil and water probe:

Installed in the oil chamber to detect the leakage of the first mechanical seal (in the medium). When the leakage medium reaches the oil chamber, it will report with an alarm signal.

2). Float switch

Installed in the motor cavity to detect the leakage of the second mechanical seal. When the oil (oil-water mixture) enters the motor, the float switch will report with an alarm signal and stop the pump.

3). Thermosensitive components

Installed in the motor stator winding. If the motor is overloaded or the motor winding temperature (or other reasons cause motor winding heating) reaches a certain value, it will report with an alarm signal and the pump will be stopped.

11.External control system

The special electric control cabinet can process all kinds of signals in the pump to realize the functions of control, protection, sound-light alarm and a variety of automatic control of single pump and multiple pumps.

When the user uses their own electric control cabinet, shall contact our electric control cabinet professional group to guide the user to install the protection controller in the electric control cabinet.

12.Optional

Forced cooling system. The motor housing is equipped with metal sleeve to introduce cooling circulation water and achieve forced cooling.

13.Performance curve and main parameters

The actual portion of the curve on the performance graph indicates the recommended range of use for the pump. The shaft power of the pump rises as the flow rate increases. If the flow rate of the pump exceeds the flow limit on the right, the shaft power will exceed the rated power of the motor. When the medium temperature is high or the motor is not sufficiently cooled, the motor cannot work for a long time; If the flow rate is less than the flow limit on the left, the shaft power of the pump is much lower than the rated power of the motor, and the efficiency of the unit is very low. It is very uneconomical to use the pump under such conditions.

Key words:

Product Packaging

Company Information

Shijiazhuang Zhengrong Pump Co., ltd., affiliated with Shijiazhuang Industrial Pump Co., ltd.Group, is a large-scale slurry pump manufacturing enterprise. ZR provides slurry pump and special alloy parts that feature a high performance and a wearing and corrosion resistance. First established in 1998, we now own three production bases with a dredge pump, desulphurization pump and slurry pump production base located in Shijiazhuang Development Zone, covering 46000 square meters.

ZR can complete the research and development of new products, due to our self-owned pump test station, which carries out tests with extreme accuracy to ensure all pumps meet international standards, and allow us to offer only the best products and materials to meet different operating conditions. We have a large mold database that includes a full range of advanced aluminum molds used to produce various industrial pump castings. Our company has an extensive inventory of standard pieces, allowing us to keep a delivery period to within 10 days of the order being placed. If standard products don’t meet your needs, supply us with special design drawings, and we will carry out custom OEM orders for even the most advanced EPC casing line. We work with numerous well-known domestic names, including the Waterway Bureau, mining companies, desulphurization companies and more, as well as partnerships with international corporation customers.

Our product line includes pumps and accessories, and OEM services, and has been sold around the world to customers from North and South America, Africa, Russia, Europe and Southeast Asia. Come check us out today, and let ZR show you what we have to offer for all of your slurry pump needs.

Our Services

1. Processing with supplied drawing

2. Processing with supplied samples

3. Produce all kinds of anti abrasive spare parts except for pump

Shipping And Payment

FAQ

How can I make order online?

Do you have MOQ limit?

Which payments are acceptable?

Which shipping terms are available?

How about the delivery time?

Can I purchase parts separately?

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products