Riding the Wave: Why Your Slurry Pump Pressure is Fluctuating

Date:

2025-09-20

Riding the Wave: Why Your Slurry Pump Pressure is Fluctuating

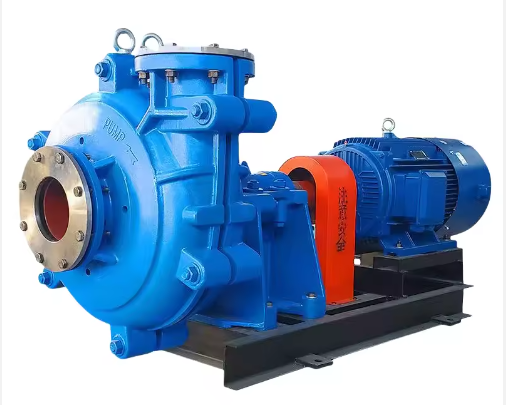

A slurry pump is the heartbeat of many heavy-duty operations. You expect it to deliver a consistent, powerful flow, moving your abrasive mixture from point A to point B. So, when the pressure gauge starts dancing erratically, it's more than just an annoyance—it's a cry for help from your system.

Pressure fluctuations, often felt as pump "surges," are a classic symptom of an imbalance between what the pump is trying to do and what the system is allowing it to do. Ignoring these surges leads to inefficient operation, higher power consumption, increased wear on components, and ultimately, premature failure.

Let's dive into the most common culprits behind this unstable behavior.

The Usual Suspects: What's Causing the Surge?

Think of your slurry pump system as a chain. Every link needs to be strong for the entire thing to work. A fluctuation often means one of these links is weak.

1. Cavitation: The Number One Enemy

This is the most frequent cause of severe pressure fluctuations and it sounds exactly as bad as it is.

What is it? Cavitation occurs when the pump's suction side isn't getting enough fluid. The pump creates such a low pressure that the liquid itself literally boils, forming tiny vapor bubbles. These bubbles then travel into the high-pressure zone of the pump, where they violently collapse.

What does it feel/sound like? It often sounds like the pump is pumping gravel—a distinct rattling or cracking noise. The pressure gauge will jump up and down wildly.

Common Causes:

Clogged Suction Line: A blockage in the pipe or a clogged strainer restricts flow.

Insufficient NPSHa (Net Positive Suction Head available): The system doesn't have enough pressure pushing fluid into the pump. This can be due to:

The pump being placed too high above the sump.

The suction pipe being too long or having too many bends.

Running the pump too fast for the system's capabilities.

2. Inconsistent Feed & Air Ingestion

Your pump wants a steady diet of slurry. A erratic feed creates an erratic output.

What is it? If the level in your feed tank or sump varies too much, the pump will alternately handle a full stream of slurry and then gasp for a mixture of air and fluid.

What does it feel/sound like? The pump output will pulse, and you might hear gurgling or sucking sounds from the suction line.

Common Causes:

Low Sump Level: The pump vortexes and draws air into the system.

Poor Flow Design: The feed isn't entering the sump smoothly, creating vortices that pull in air.

Leaks on the Suction Side: Any air leak in the suction pipe, fittings, or even the gland seal will cause air to be drawn into the pump.

3. The Pump Itself: Wear and Tear

Slurry pumps are designed to handle abuse, but they aren't immortal. Wear will change the pump's performance characteristics.

What is it? As the impeller and volute (or liner) wear, the clearances between them increase. This allows slurry to recirculate inside the pump instead of being pushed efficiently out the discharge.

What does it feel/sound like? The pump may seem like it's working harder (higher amperage) but delivering less pressure and flow. Fluctuations can occur as the flow becomes unstable.

Common Cause:

Normal Operation: Abrasive wear is a fact of life with slurry. Regularly monitoring performance and scheduled maintenance is key.

4. System Design & Operation Issues

Sometimes the issue isn't a single component, but how the entire system is set up or run.

Operating Too Far from the BEP (Best Efficiency Point): Every pump has a sweet spot on its performance curve. Running it too far to the left (low flow) or right (high flow) of this point causes unstable flow, recirculation, and excessive vibration, all contributing to pressure swings.

Wrong Impeller Speed/Diameter: Using a variable frequency drive (VFD) or a different impeller size that isn't suited to your system's resistance (system curve) can push the pump into an unstable operating region.

The Troubleshooting Checklist: How to Find the Culprit

Listen: Does it sound like it's pumping rocks? It's almost certainly cavitation.

Look:

Check the suction tank/sump level. Is it stable and high enough?

Inspect the suction line for visible leaks or clogged strainers.

Look at the gland seal area. Is it spraying or pulling in air?

Feel: Is the suction hose collapsing? This is a clear sign of a suction restriction.

Review: Have you recently changed speed (VFD settings) or opened/closed valves? A valve on the discharge side that is too closed can cause cavitation.

Conclusion: Stability Through Steadiness

Pressure fluctuation is a symptom of instability. The solution almost always involves ensuring a consistent, air-free, and sufficient supply of slurry to the pump's inlet. By methodically checking your system—from the sump level to the impeller wear—you can calm the waves, protect your pump, and ensure a smooth, efficient, and reliable operation.

Struggling with persistent surges in your system? Our engineering team can help you analyze your pump curves and system design to find a stable solution. Contact us today for expert support.

Jack Wan +86 15364966178

Keywords:

Related News

Why Is Your New Slurry Pump Underperforming?

2025-09-22