Dealing with Wear-Induced Leaks in Slurry Pumps and Pipelines

Date:

2025-09-22

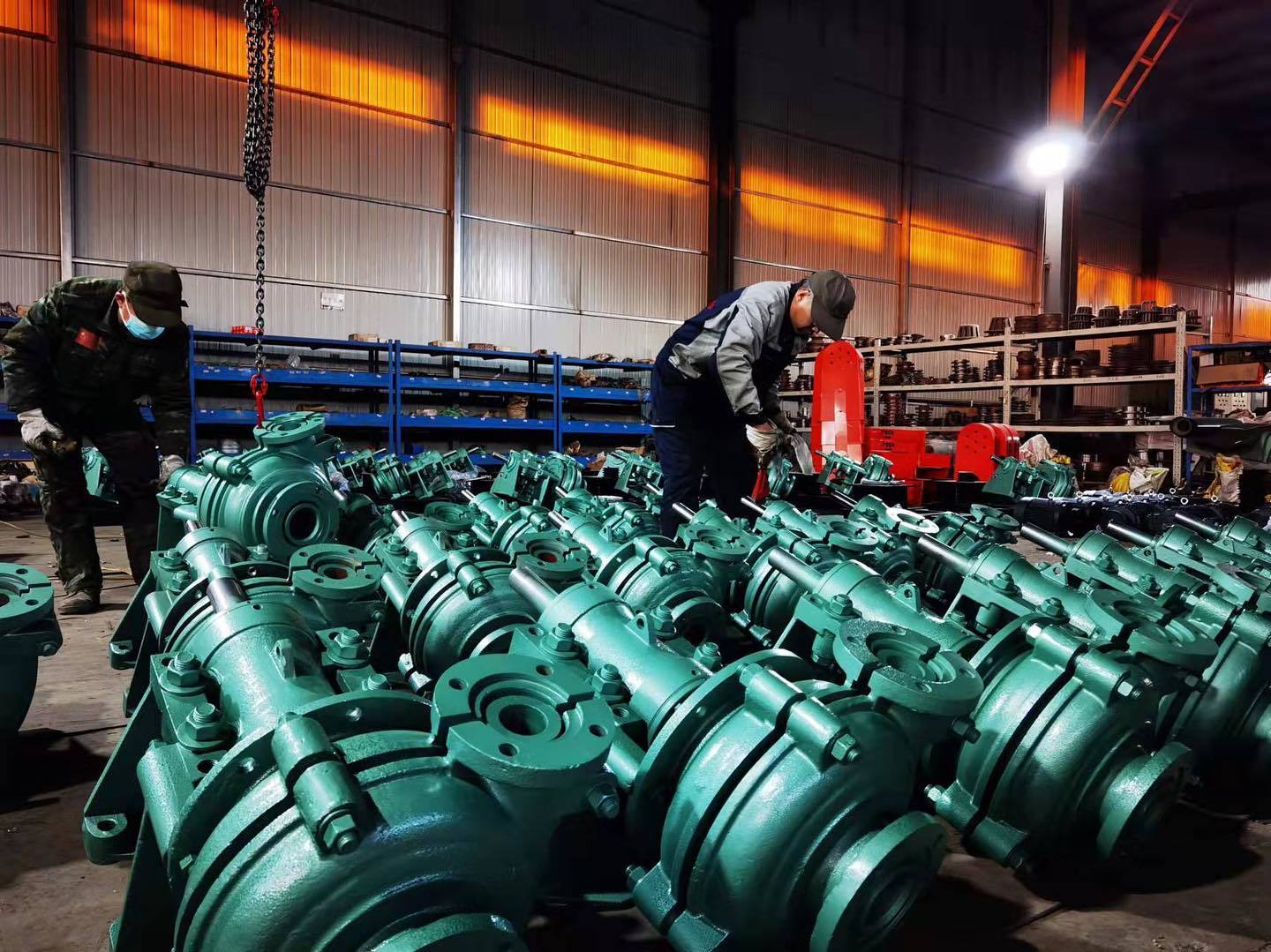

Dealing with Wear-Induced Leaks in Slurry Pumps and Pipelines

Slurry pumps are built tough, but they’re not invincible. When abrasive particles constantly rush through the system, even the most robust materials can eventually wear down—sometimes to the point of leaking. So, what should you do if your slurry pump casing or pipeline gets worn through? Let’s break it down.

🚨 First Steps: Dealing with a Leak

If you notice slurry leaking from the pump or pipes:

Stop the Pump Immediately

Continuing to run the pump can worsen the leak, cause safety hazards, and lead to more extensive damage.

Isolate and Secure the Area

Depending on what’s in the slurry (e.g., chemicals, minerals), leaking fluid can be slippery or environmentally sensitive. Contain the leak if possible.

Drain and Clean the System

Before any repair, make sure the pump and affected pipe sections are emptied, cleaned, and safe to work on.

🛠️ Repair or Replace?

Your next move depends on the severity and location of the wear.

For Localized Damage (Small Holes/Cracks):

Patch Repairs:

Temporary welding or epoxy-based patching (like wear-resistant putty) can seal small holes. This is a short-term fix—ideal to minimize downtime while planning a permanent solution.

Bandage Clamps or Sleeves:

Mechanical clamps with rubber seals can be used externally on pipes for quick leakage control.

For Severe or Large-Scale Wear:

Replace the Section:

If a segment of the pipe or a part of the pump volute is badly worn, replacement is often the best and most reliable option.

Upgrade the Material:

If wear is recurring, consider switching to more abrasion-resistant materials. For example:

High-chrome iron castings

Rubber-lined or polyurethane-lined components

Ceramic-coated wear parts

🔍 Why Did It Happen? Understanding the Root Cause

Fixing the leak isn’t enough—you need to prevent it from happening again.

Common causes of wear-through:

Abrasive Slurry Characteristics:

High concentration, large or sharp particles, and high flow speed accelerate wear.

Material Compatibility:

The pump or pipeline material may not be suitable for the type of slurry being handled.

Poor System Design:

Sharp bends, sudden diameter changes, or long straight runs without rotation can cause accelerated localized wear.

Cavitation + Abrasion:

As mentioned in our previous blog, cavitation damages surfaces, making them more vulnerable to abrasion.

✅ Prevention Is Better Than Cure

Here’s how to protect your system:

Regular Inspections:

Use ultrasonic thickness gauges to monitor wear in pipes and pumps without disassembly.

Use Wear Protection:

Install removable wear plates or liners in high-wear areas. Replace these instead of the whole structure.

Optimize Flow Conditions:

Maintain proper flow velocity—not too low (settling) and not too high (accelerated wear). Design pipelines with sweeping bends instead of sharp turns.

Choose the Right Materials:

Match material grade to slurry abrasiveness. Consult with slurry pump experts for the best selection.

👷 When to Call the Experts

If you’re dealing with:

Repeated failures in the same area

Uncertainties in material selection

System design limitations

…it might be time to get a professional involved. We help diagnose wear problems, recommend materials, and even redesign systems for longer service life.

💡 Conclusion

A worn-through slurry pump or pipeline is a serious issue, but it doesn’t have to mean disaster. Respond quickly, repair wisely, and use the opportunity to improve your system’s wear resistance.

Need support with your slurry handling system? Reach out—we’re here to help keep your operations running smoothly.

Enginner : Jack +8615364966178 info@xo-pump.com

Keywords:

Related News