How to choose the appropriate seal for your working conditions?

Date:

2025-09-19

Common Sealing Methods for Slurry Pumps and How to Select the Right One

How to choose the appropriate seal for your working conditions?

Firstly, we need to know the common sealing methods used. Slurry water pumps are commonly used to transport media containing abrasive particles, and their sealing needs to balance wear resistance and leakage prevention. The following are the three most common sealing methods for slurry pumps:

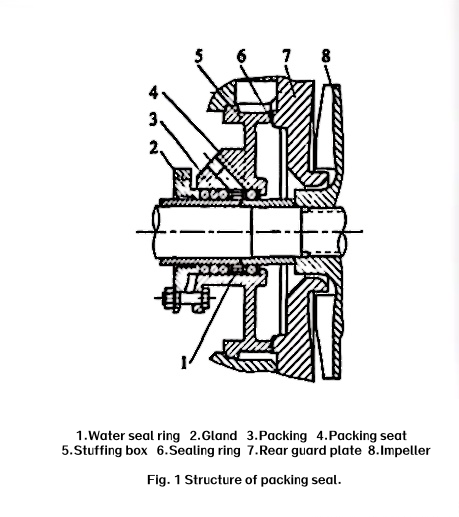

1.Packing Seal

Soft packing is inserted into the stuffing box (packing chamber) and compressed with a gland, creating a seal against the cylindrical surface of the shaft or sleeve (Fig. 1). The fundamental requirement for a packing seal is to inject pressurized clean water (known as shaft seal water) through the shaft seal water port, with its pressure greater than the pump’s discharge pressure. The primary functions of the packing shaft seal are to prevent slurry from leaking outward and to avoid air ingress into the pump cavity, which is particularly critical for suction-mounted pumps.

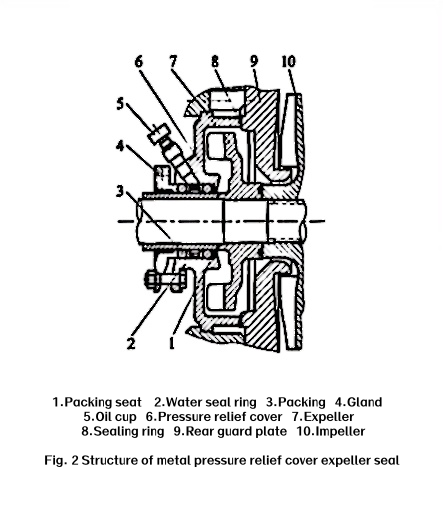

2. Expeller Seal

An expeller seal operates based on hydrodynamic principles and is a non-contact type of seal. Air or clean water, under the rotational action of the expeller, generates pressure that forms an air-slurry or water-slurry balance at the outer edge of the expeller, counteracting leakage from the main impeller’s discharge. Expeller seals are primarily used for sealing low-pressure liquids containing impurities, with the drawback of higher power consumption. There are two structural types of expeller seals: the metal decompression cover expeller seal and the rubber decompression cover expeller seal. The former is generally more common. The structure of the metal decompression cover expeller seal is shown in Fig. 2.

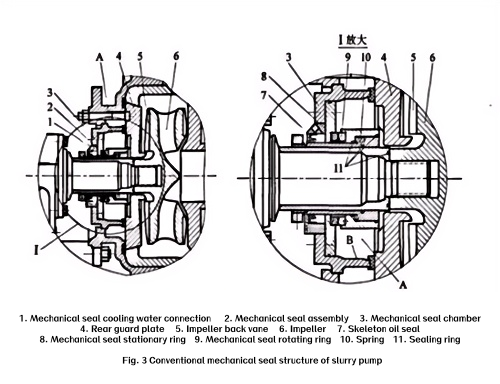

3. Mechanical Seal

The mechanical seal structure consists of a rotating ring (which rotates with the shaft and can move axially), a stationary ring, a compression element (spring), and sealing elements (sealing rings), among others. The rotating ring, under the pressure of the compression element and the liquid pressure in the seal chamber, presses its end face against the stationary ring’s end face. The rotating and stationary rings, under pressure and relative rotational motion, establish hydrodynamic lubrication between their end faces. The closely fitted end faces of the rotating and stationary rings, along with the action of the sealing rings, block all potential paths for fluid leakage from the pump chamber, thereby creating a seal between the rotating component (sleeve or shaft) and the stationary component (pump casing) to achieve sealing (see Figs. 3 and 4). Due to their high reliability, long service life, and strong adaptability to external conditions, mechanical seals are widely used in many industries and have gradually become the preferred recommended shaft sealing solution for slurry pumps.

There is no absolute 'best' choice, only 'most suitable'.

For most common abrasive slurries (such as mines, power desulfurization, dredging), the combination of "expeller+parking packing seal" is usually a time tested, economical, and reliable golden choice.

For situations with limited budget, allowance for minor leaks, and easy maintenance: traditional packing seals (perhaps combined with new improved structures) are still a feasible option.

For situations where hazardous, toxic, expensive media or environmental requirements are extremely strict, a reliable flushing solution (such as Plan 54/55) with double end mechanical seals is a safer choice, despite higher initial costs and maintenance complexity.

Always consult a professional: Before making a final decision, it is strongly recommended to consult with a pump manufacturer or a professional sealing technology supplier. They can provide the most accurate selection recommendations based on your specific operating parameters (medium details, flow rate, head, temperature, etc.).

Keywords:

Related News

Why Is Your New Slurry Pump Underperforming?

2025-09-22